Understanding Original, Remanufactured and Compatible cartridges

TonerMarket offers a full range of Genuine (or Original) Cartridges as well as Remanufactured and Compatible Cartridges. Most users are not aware of the relative benefits and specific differences between Remanufactured Cartridges and Compatibles. This Product Guide gives a brief overview of the relative benefits of each.

Did you know that in Australia approximately 75-80% of all toners that are sold are Original Equipment Manufacturers (i.e. OEM or genuine branded)? The balance of only 20-25% are sold as Compatibles or Remanufactured. Most of these OEM’s end up in landfill despite having the potential of being reused 3 or more times. This contrasts with the US where the ratios are approximately the opposite. Why? We believe the reason in large part is because exposure to poor quality Compatibles in the past has left many consumers with an unwillingness to retry these products despite major improvements in quality.

Tonermarket provides an extensive range of quality alternatives to OEM’s that offer the consumer substantial savings without compromising on quality and at the same time contribute to improving the environment in a very real way. We can do this because we focus on sourcing our product from only proven quality suppliers.

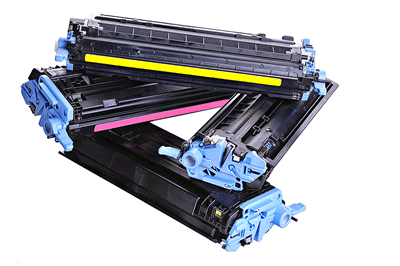

Remanufactured Toners

Remanufactured toners are the closest equivalent to the Genuine or OEM (Original Equipment Manufacturer) because they utilize some of the existing Genuine components including the shell of a Genuine cartridge as well as any parts that can be re-qualified (i.e. inspected and approved for reuse). Any components that are worn, damaged, or do not meet stringent quality standards are simply replaced with brand new parts.

The best remanufacturers of cartridges test each and every toner in their production with a thorough print run to ensure superior quality standards.

Cartridge RescueTM is the premium quality brand producer of Remanufactured Cartridges in Australia. With their process and quality assurance, they offer a fail rate of under 1%.

The Remanufacturing Process

Used cartridges undergoing remanufacturing are first disassembled and the parts inspected. The key parts include the drum, corona wire assembly, wiper blade, and roller. Worn or defective parts are replaced, and the cartridge is cleaned, refilled, and reassembled. Toner cartridges can be remanufactured several times.

Not All Recycled Cartridges are Created Equal

Some remanufacturing companies simply drill a hole in the side of the cartridge and refill it with toner, and do not clean the cartridge and repair broken parts. These “drill-and-fill” operations do not produce quality remanufactured toner cartridges. A “split-hopper” cartridge is another type of remanufactured toner cartridge that may not provide consistent performance. When the toner hopper is split during the remanufacturing process, clips must be installed to secure the halves back together. Clips may become loose or fall off when the cartridge is in use, causing the printer to jam or result in other problems.

Can my machine use a Remanufactured cartridge?

Any office equipment that uses a toner cartridge, excluding those requiring toner to be added to the machine, should be able to use a remanufactured toner cartridge. We supply customers with remanufactured toner cartridges and can easily organize for the collection of spent cartridges. Buying remanufactured toner cartridges and recycling empty cartridges are easy ways to reduce the environmental impact of these products while saving money.